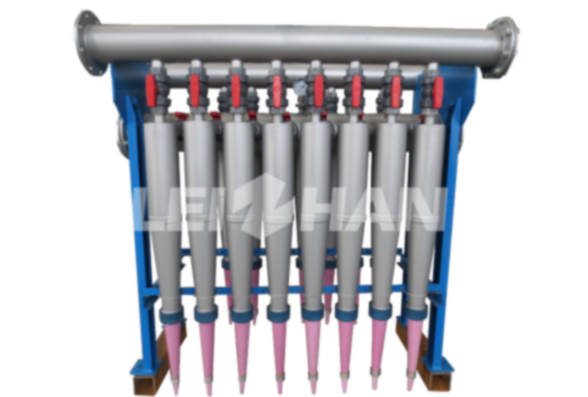

KH Series Low Density Cleaner

KH Series Low Density Cleaner is mainly used for removing heavy impurities in the pulp like gravel, scrap iron, dust and large ink particles in paper making process.

Waste paper pulp cleaning equipment KH Series Low Density Cleaner is mainly used for removing heavy impurities in the pulp like gravel, scrap iron, dust and large ink particles.

Application & Features

- Divided design, the cleaners can be divided into 3-4 parts, which make it easier for disassembly, assembly and replace.

- Different deslagging ways: open and closed type impurity discharge to meet different working environment.

- The bottom of cone adapt wear-resistant ceramics. It ensures the stable deslagging and long service life.

Main specification

| Type | KH-400 | KH-600 |

| Rate passing capacity of single equipment(L/min) | 400 | 600 |

| Inlet consistency(%) | 0.3-1 | 0.3-1.2 |

| Pressure of inflow pulp(Mpa) | 0.2-0.4 | 0.2-0.4 |

| Diameter of deslagging outlet(L/min) | 3-14 | 6-16 |

| Type | KH-800 | KH-1000 | KH-1500 |

| Rate passing capacity of single equipment(L/min) | 800 | 1000 | 1500 |

| Inlet consistency(%) | 0.4-1.2 | 0.4-1.5 | 0.4-1.5 |

| Pressure of inflow pulp (Mpa) |

0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

| Diameter of deslagging outlet (L/min) |

6-14 | 6-18 | 6-18 |

Capacities vary depending on feed size, feed rate, operating conditions, desired product output, characteristics of feed material, and equipment configuration

Download complete technical literature [PDF]